Kaltra stands as an international beacon, illuminating the path toward a more sustainable future through its innovative cooling solutions. But what exactly sets this Munich-based company apart in a world increasingly concerned with energy consumption and environmental impact? The answer lies in their dedication to crafting energy-efficient chillers, free cooling systems, precision air conditioners, and of course, microchannel heat exchangers. These aren’t just products; they’re carefully engineered solutions designed for the demanding environments of data centers and diverse industrial applications. And with operations spanning over 60 countries, Kaltra’s influence is truly global.

Kaltra’s Commitment to Environmental Friendliness

In today’s world, environmental friendliness isn’t just a buzzword, it’s a necessity. How does Kaltra address this imperative? Their approach is multifaceted, starting with the very design of their products. By prioritizing energy efficiency, they minimize the environmental footprint of their solutions. Each cooling condenser and system is crafted with sustainability in mind, reducing energy consumption and minimizing waste.

Beyond efficient design, Kaltra also invests in research and development to continuously improve their offerings. This proactive stance allows them to stay ahead of the curve, anticipating future environmental regulations and exceeding industry standards. This commitment extends to the materials they use and the manufacturing processes they employ.

The Significance of Reliability in Industrial Cooling

Imagine a data center experiencing a cooling system failure. The potential consequences are severe, ranging from data loss to significant financial repercussions. This is where Kaltra’s focus on reliability becomes paramount. Their products are built to withstand the rigors of continuous operation in demanding environments, assuring dependability and minimizing downtime.

What contributes to this exceptional reliability? Rigorous testing and quality control measures are integral to Kaltra’s manufacturing process. Each component is carefully selected and tested to ensure it meets the highest standards of performance and durability. Furthermore, their systems are designed with redundancy in mind, providing backup capabilities that prevent catastrophic failures.

Microchannel Heat Exchangers; A Game Changer

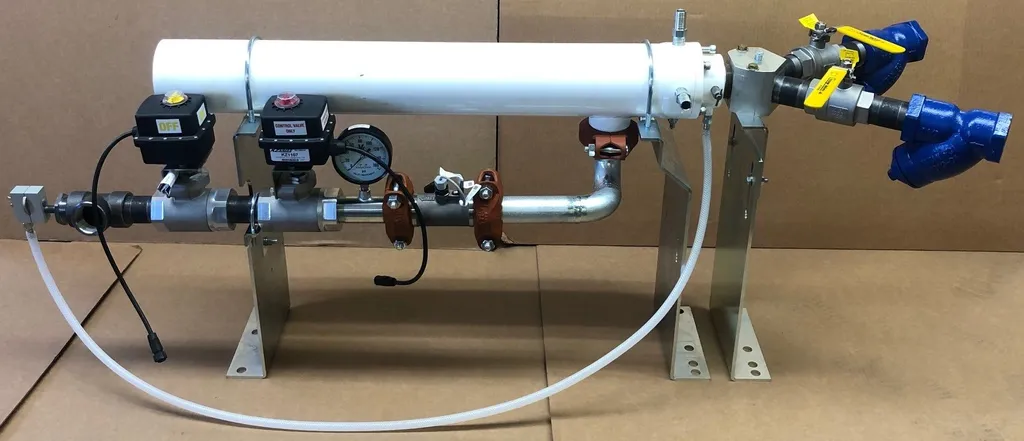

One of Kaltra’s standout products is their microchannel heat exchanger. What makes this technology so revolutionary? Traditional heat exchangers often suffer from inefficiencies due to their design and materials. Microchannel heat exchangers, on the other hand, utilize a network of tiny channels to maximize heat transfer efficiency. This results in reduced energy consumption and improved cooling performance.

These heat exchangers are particularly well-suited for data centers, where high density computing generates substantial heat loads. By efficiently dissipating this heat, Kaltra’s microchannel heat exchangers help data centers operate more efficiently and reliably. Similarly, industries that rely on precise temperature control, such as pharmaceuticals and manufacturing, can benefit significantly from this technology. The cooling condensers are designed for optimal performance.

Serving Data Centers and Industry Alike

Kaltra’s solutions aren’t confined to a single industry; they cater to a diverse range of applications. Data centers, with their immense energy demands, are a primary focus. Kaltra’s chillers, free cooling systems, and precision air conditioners are designed to meet the unique challenges of these environments, providing efficient and reliable cooling solutions that minimize energy costs and reduce environmental impact.

But their expertise doesn’t stop there. Kaltra also serves a wide array of industrial clients, from food processing plants to chemical manufacturing facilities. These industries often require specialized cooling solutions to maintain product quality, ensure worker safety, and comply with environmental regulations. Kaltra’s ability to tailor their products to specific needs makes them a valuable partner for companies seeking to optimize their cooling processes.

The Future of Energy-Efficient Cooling

As the world becomes increasingly conscious of energy consumption and environmental impact, the demand for energy-efficient cooling solutions will continue to grow. How is Kaltra positioning itself to meet this challenge? By remaining at the forefront of innovation, investing in research and development, and maintaining a steadfast commitment to environmental friendliness and reliability. Kaltra’s dedication to crafting advanced cooling condenser technology ensures they will be ready for the future. They are not just manufacturing products; they are shaping a more sustainable future for industries worldwide. Their global reach and unwavering focus on quality make them a key player in the evolution of energy-efficient cooling.